- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 326932 Author: Site Editor Publish Time: 2025-11-10 Origin: Site

The glass laminating process is an essential step in modern glass manufacturing that enhances both safety and aesthetics.

At TopoGlass, a professional glass factory and processing manufacturer based in Guangzhou, China, we specialize in producing high-performance laminated glass through advanced equipment and precision technology.

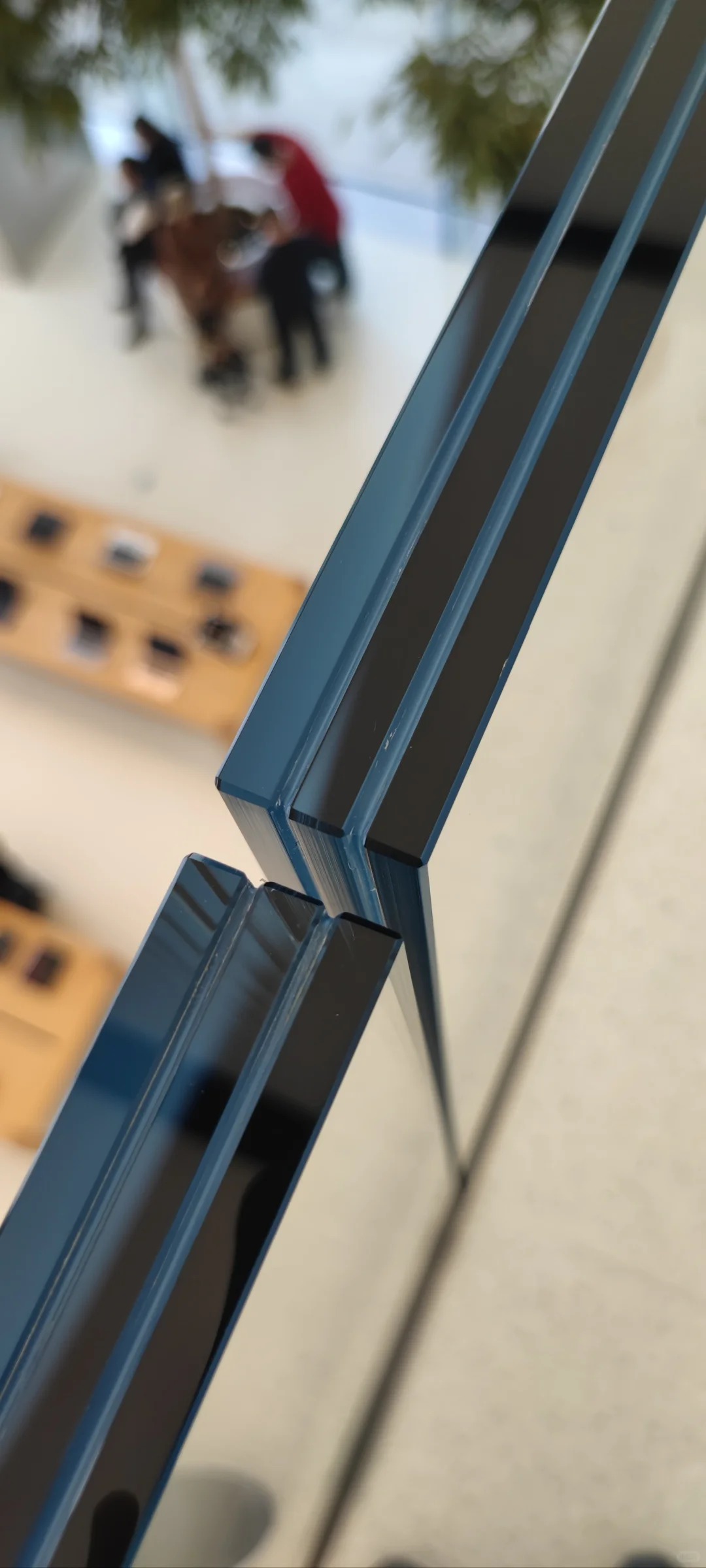

The glass laminating process involves bonding two or more layers of glass together with an interlayer film, such as PVB, EVA, or SGP, under high temperature and pressure.

This process creates a single, durable panel that maintains clarity while offering superior strength, safety, and sound insulation.

Typical structure:

Glass Sheet + Interlayer Film + Glass Sheet → Laminated Glass Panel

Glass Cutting and Cleaning

Each glass sheet is precisely cut to the required size and thoroughly cleaned to remove dust and contaminants.

Interlayer Placement

A film (usually PVB, EVA, or SGP) is placed between two sheets of glass.

Pre-Pressing

The glass sandwich is pre-heated and pressed to remove air bubbles and ensure firm adhesion.

Autoclaving (High-Pressure Heating)

The glass is placed in an autoclave where heat and pressure complete the bonding, forming a strong and safe laminated glass panel.

Inspection and Edge Finishing

After cooling, each panel undergoes strict quality inspection, edge polishing, and packaging for delivery.

Safety: The interlayer prevents the glass from shattering into sharp pieces upon impact.

Sound Insulation: Excellent noise reduction performance.

UV Protection: Blocks up to 99% of harmful UV rays.

Durability: Resistant to weathering and moisture.

Aesthetic Variety: Can include colored films, patterned interlayers, or decorative materials like bamboo, fabric, or metal mesh.

TopoGlass laminated glass is widely used in:

Architectural projects: curtain walls, skylights, facades, balustrades

Interior decoration: partitions, doors, furniture glass

Automotive glass and display showcases

Special design glass: bamboo interlayer glass, jade glass, AR anti-reflective glass, and more

As a trusted glass manufacturer and processor in Guangzhou, TopoGlass provides:

Advanced laminating lines with strict quality control

Support for custom designs, colors, and interlayer materials

Professional OEM/ODM services for B2B clients

Competitive pricing and global export experience

At TopoGlass, we don’t just process glass — we engineer beauty, safety, and innovation into every panel.

The glass laminating process is more than just combining glass layers — it’s a fusion of technology, craftsmanship, and creativity.

TopoGlass continues to innovate in laminated glass production, providing reliable, customizable, and sustainable glass solutions for partners around the world.

| | No.2 Hongfeng Road, Yunpu Industrial Zone, Nangang, Huangpu District, Guangzhou, Guangdong China |

| | +86-180-11896423 |

| |